Iron*, Manganese*, Hydrogen Sulfide* and Arsenic* Removal Filter

FEATURES AND BENEFITS

MADE IN THE USA

Solid state microprocessor with easy access front panel settings

Three modes of operation; meter immediate, meter delayed, or time clock delayed

Double backwash feature offers optimum regeneration, cleaning ability, and efficiency

Capable of 36 pre-programmed regeneration cycles based on control valve setting

Days override feature; 1 – 28 days available

Backwash and brining ability to 21” diameter tanks

Downflow/upflow regeneration

Stores system configuration and operation data in nonvolatile memory

Coin Cell Lithium battery back-up with an 8 hour carry over

Level VI 15-volt output DC power supply provides safe and easy installation

Control valve design provides optimum service and backwash rates

Reliable and proven DC drive

One piece expanding seal spacer stack assembly

Linearly reciprocating piston operation

SPECIFICATIONS

| GENERAL | |

| Inlet/Outlet Fitting Connections | 1” – 1.25” NPT ¾” – 1.5” Sweat ¾” – 1.5” Solvent ¾” – 1” SharkBite® ¾” – 1” John Guest® |

| Cycles | up to 6 |

| Valve Material | Fiber Reinforced Composite |

| Regeneration | Downflow/Upflow |

| Operating Pressures | 20 – 125 psi |

| Operating Temperatures | 40° – 110° F |

| Options | Backwash Filter, Bypass, Weather Cover |

| FLOW RATES | |

| Service @15 psi drop includes meter and bypass |

27 gpm |

| Backwash @25 psi drop includes bypass |

27 gpm |

| Cv Service | 7.0 |

| Cv Backwash | 5.4 |

| TANK APPLICATIONS | |

| Water Softener | 6” – 21” diameter |

| Water Filter | 6” – 21” diameter Filter tank size calculated @ 10 gpm of backwash per square foot of bed area |

| METER | |

| Accuracy | ± 5% |

| Flow Rate Range | 0.25 – 27 gpm |

| Gallon Range | 20 – 50,000 gallons |

| Totalizer | 1000 – 9,999,000 gallons |

| DIMENSIONS & WEIGHT | 1.050″ OD PIPE (¾” NPS) |

| Drain Line | ¾” or 1” NPT |

| Brine Line | 3/8” or ½” OD Poly Tube |

| Mounting Base | 2 1/2” – 8 NPSM |

| Height From Top Of Tank | 7 3/8” |

| Weight |

|

ALDEX CR Series

CR 26 Iron*, Manganese*, Hydrogen Sulfide* and Arsenic* Removal Media

NSF/ANSI/CAN 61-2022 Certified. Aldex CR 26 is a special media designed to provide excellent catalytic properties required for removal of many contaminants from potable and non-potable aqueous streams. Aldex CR 26 is an insoluble media that oxidizes species in solution including hydrogen sulfide, iron and manganese. Metal-oxide nano-particles are precipitated within the resin bed

where they form very strong chemical bonds with arsenite (As III) and arsenate (As V). Aldex internal testing concludes Aldex CR 26 media thoroughly and effectively removes arsenic, Fe, Mn and H2S.

*Claims reduction verified by manufacturer internal testing only.

Aldex CR 26 Technical Bulletin: US Units (PDF)

Aldex CR 26 Safety Data Sheets: English (PDF)

Physical Chemical Properties

| Physical Form: | Black, moist spherical beads |

| Moisture Content: | 46 to 52% |

| Net Weight (as shipped): | 800 kgs/m3, approximately |

| Particle size: >1.2 mm % <0.3 mm % |

0.3 to 1.2 mm 5.0 maximum 1.0 maximum |

| Effective Size: | 0.50 to 0.60 mm |

| Uniformity Coefficient: | 1.7 maximum |

Recommended Operating Conditions

| Influent pH: | 6.0 to 9.0 |

| Dissolved oxygen: | 2 mg/l or 15% greater than Iron (Fe) content |

| Freeboard: | 30% to 50% |

| Free chlorine: | 0.5 to 1.0 mg/l |

| Organic matter: | Less than 1.0 ppm |

| Total dissolved solids: | 2500 ppm maximum |

| Total suspended solids: | < 1 ppm maximum |

CR 26 Features

Chemical Free Regeneration

Aldex CR 26 does not require chemicals such as chlorine dioxide, potassium permanganate, chlorine or sodium chloride brine solution for regeneration. The oxidative chemical locked inside Aldex CR 26 beads is regenerated via the dissolved oxygen in the backwash water.

Potable and Non-Potable Water Applications

Aldex CR 26 requires less contact time and is like standard softening resins in bulk density and handling making it an ideal choice for point-of-entry (POE) systems. Aldex CR 26 can be backwashed at lower flow rates to achieve ideal bed expansion needed to remove metal-oxide precipitates generated during the service cycle. Aldex CR 26 is easy to handle versus other oxidative media and many naturally occurring zeolites.

Multiple Contaminant Removal

Aldex CR 26 was initially designed for the selective removal of iron and manganese but testing has shown the product to be ideal for multi-contaminant removal. See below for a summary of various tests performed to date.

Expected Service Life

Due to the unique nature of Aldex CR 26 and its function as an oxidizing agent encapsulated within an ion exchange bead, a long service life of 3 to 4 years is expected.

CR 26 Operating Suggestions (POE Systems)

8 to 10 ppm feed iron

| Bed depth: | 30″ |

| Maximum flow rate: | 2.0 US GPM per square foot resin |

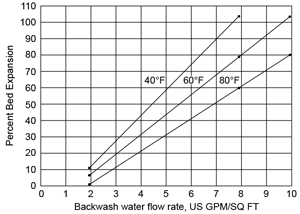

| Backwash velocity: | 5.0 to 6.0 US GPM per square foot resin at 50°F* |

| Backwash time: | 10 to 15 minutes |

| Bed Expansion: | 50 to 60% |

| Backwash frequency: | Daily |

5 to 7 ppm feed iron

| Bed depth: | 30″ |

| Maximum flow rate: | 2.5 US GPM per cubic foot resin |

| Backwash velocity: | 5.0 to 6.0 US GPM per square foot resin at 50°F* |

| Backwash time: | 10 to 15 minutes |

| Bed expansion: | 50 to 60% |

| Backwash frequency: | Daily |

1 to 5 ppm feed iron

| Bed depth: | 30″ |

| Maximum flow rate: | 4.0 US GPM per cubic foot resin |

| Backwash velocity: | 5.0 to 6.0 US GPM per square foot resin at 50°F* |

| Backwash time: | 10 to 15 minutes |

| Bed expansion: | 50 to 60% |

| Backwash frequency: | Daily |

Fig. 1 Bed expansion** vs. backwash flow rate for various water temperatures

**Bed expansion needs to lift the CR 26 bed to top of the vessel.

Vessel Specifications (POE Systems)

| Vessel | Surface area (ft.2) |

Min. Volume (CF) |

Bed Depth (inches) |

Backwash Expansion (%) |

Backwash Flowrate (gpm) |

Backwash Flowrate (gpm/ft.2) |

|---|---|---|---|---|---|---|

| 10×54 | 0.546 | 1 | 33 | 55 | 2.7 | 5.3 |

CR 26 General Guidelines

- The media can treat water having an iron content above 10 ppm, but the process is not economical, particularly for large flow rates. Hence it is recommended to remove iron by pretreating the water by aeration, followed by clarification and filtration. Aldex CR 26 shall then be used as a polishing media.

- A small amount of chlorine between 0.5 -1.0 mg/l is acceptable. Above 1.0 mg/l should be removed before passing water through the media.

- The treated water from Aldex CR 26 will have an iron content of < 0.1 ppm.

- Aldex CR 26 removes dissolved iron from water, which is present as ferrous iron. Iron can also exist in other forms such as bacterial iron, soluble organic iron and colloidal iron. Those forms of iron cannot be removed effectively by Aldex CR 26.

- All sequestering agents including polyphosphates and meta-phosphates should be added after the Aldex CR 26 unit.

- For high iron content in feed water (> 10 ppm), it is recommended to backwash the unit with treated water, to avoid contamination of the bottom portion of the bed.

- The unit must be backwashed at a specified flow rate for effective removal of precipitated iron and suspended solids.

- The backwash frequency shall be every 12 to 24 hours for a continuously operating unit. If the unit is operated intermittently, backwash at the end of each cycle.